About

Continuous fiber reinforced composite (FRP) bars developed since the middle of in the 20th century are expected to fundamentally solve the problem of durability of concrete structures caused by steel bar corrosion.

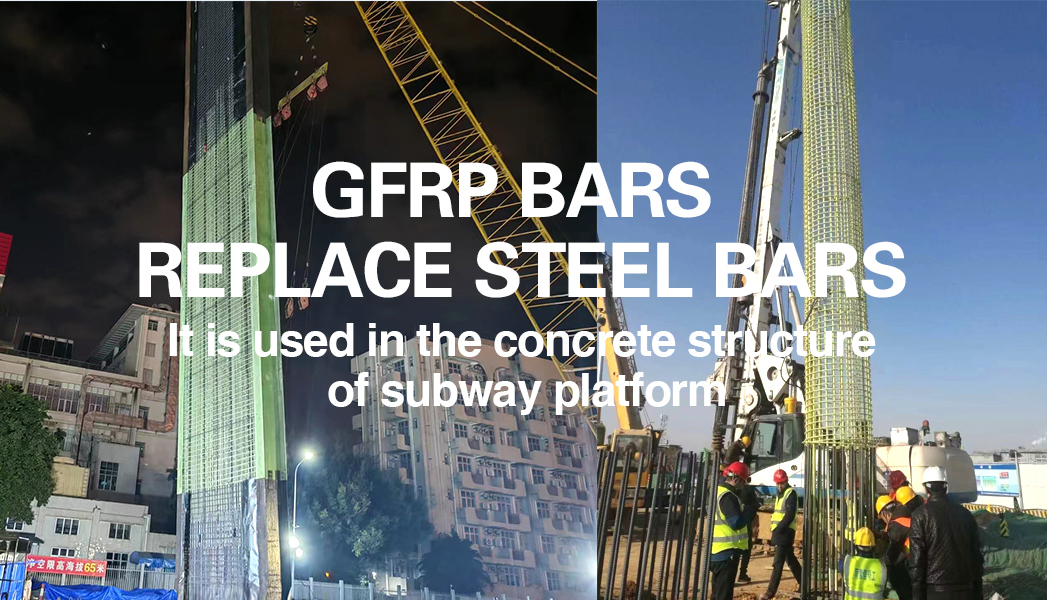

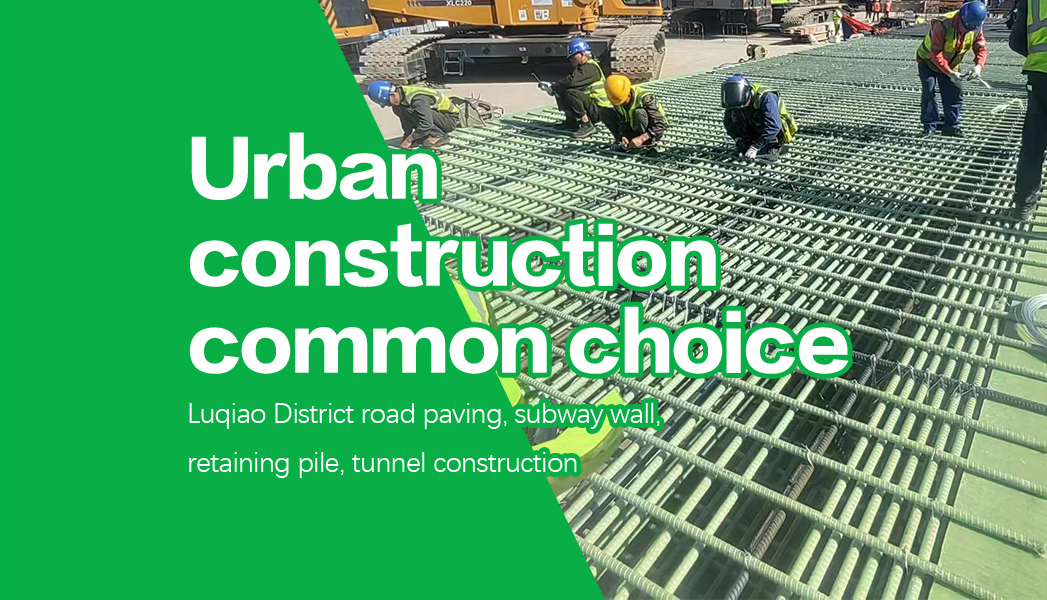

Fiber reinforced composite (FRP) reinforcement is a new type of composite material with high strength, light weight and corrosion resistance, which can be used in concrete structures instead of steel bars and prestressed bars.

A large number of studies on the mechanical properties, processing properties and structural properties of FRP bars have been carried out at home and abroad, and fruitful results have been achieved in experimental research and engineering application.

The results show that FRP bars have the characteristics of high tensile strength, low density, good bonding properties, good corrosion resistance, good fatigue resistance, good electromagnetic insulation, complete linear elastic properties and low elastic modulus.

Using FRP bars instead of reinforced concrete is an effective method to solve the problem of durability and meet the functional requirements of the structure.